Make The Most Of Your Storage Or Production Zones

Maximizing Storage Capacity

The automated AS / RS storage and retrieval system Pallet Shuttle® Four-Directional “4D” reduces labor, eliminates forklifts, and enhances inventory accuracy. Fully or semi-automated Pallet Shuttle systems can be installed alongside the existing pallet rack systems or replaced. Pallet Shuttle Systems reduces dependence on hazardous forklifts, and can be implemented with complete maintenance.

Improves Accuracy of Inventories

The Pallet Shuttle ® TRAK-IT Control System interfaces with existing ERP technologies for managing all aspects of warehouse or floor environments in production. To reduce manual and redundant forklift travel, automated Guided Vehicles (AGVs) can be integrated with Pallet Shuttle Systems. The Pallet Shuttle Automation provides turnkey design, installation of high quality, and project management services.

Improve Cubic Storage Capacity

Make most of your storage or zones of production.

Improve Inventory Accuracy

Improve customer service and purchasing functions.

Reduce Forklifts and Labor Costs

Eliminate aisles, labor requirements and forklifts.

TRAK-IT Warehouse Control

Cost efficient rapidly deployed warehouse control system.

Raw and Finish Goods Storage

Pallet Shuttle systems can be used both in storage areas for raw materials and finished goods. Configuration of the devices for both storage and picking operations. For Pallet Shuttle applications, WIP, buffer zones, staging areas, very narrow lane, medium lane, and drive-in applications are ideal matches. Pallet Shuttle Automated Storage Systems are cost efficient and can be tracked quickly for quick deployment.

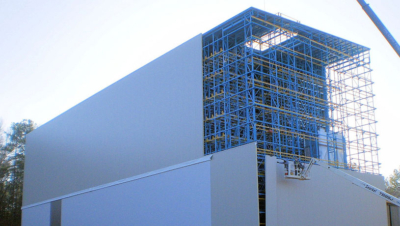

Cold Storage Systems

Completely Automated Self Contained or Rack Assisted Deep Lane Pallet Shuttle Storage and Retrieval Systems are suitable for systems with a high-density labor saving. The Omni-Directional Pallet Shuttle Systems is a better solution than the expensive crane stacker. Pallet shuttle systems provide redundant and cost efficient high-density storage. Rack supported Pallet Shuttle systems help to reduce building costs and speed up the construction process. For maximum storage capacity, Pallet Shuttle Automated Rack Supported Systems are modular and can be built very tall.

Vertical Indoor Cultivation

An excellent solution for automating Vertical Indoor Farming is the Pallet Shuttle. Using Plant-To-Person state-of-the-art growth hub technology combined with automated plant monitoring and living soil greatly reduces labor, water, and energy requirements for high capacity indoor farming systems. Systems can be supported by racks, installed in existing buildings, or constructed from the ground up. The teams of the Pallet Shuttle Automation provide turnkey design, permitting and city administration and long-term operational support.